Why should you monitor large diesel engines?

Why should you monitor large diesel engines?

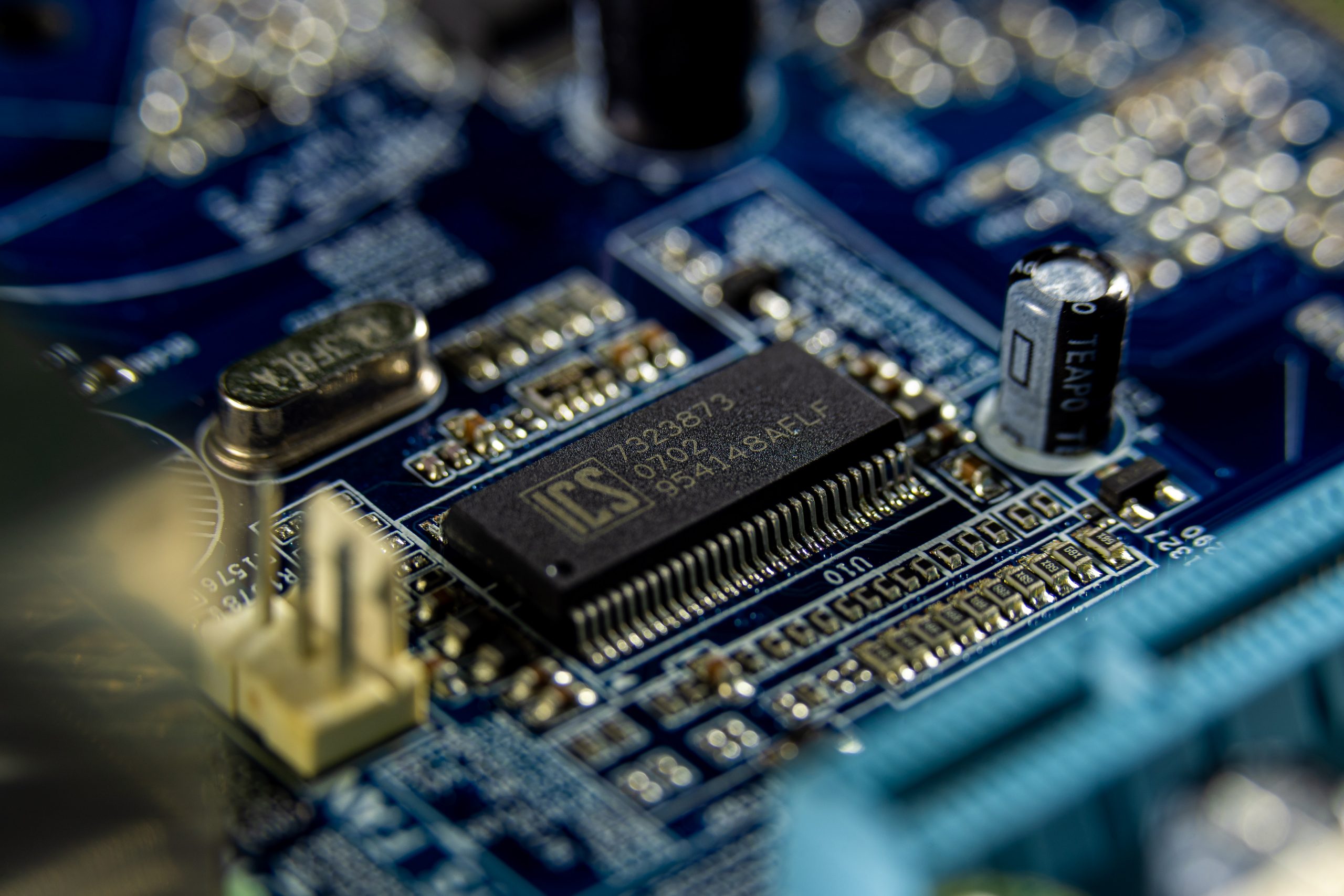

Why is diesel engine monitoring important? All machinery, regardless of their complexity or application, requires maintenance schedules. Traditionally, these have come in the form of component replacements or routine services, usually determined by a set number of operating hours. While this method is still largely in operation, it has come under review in recent years and has been replaced by innovative new monitoring methods that rely largely on complex analytics and sensors. By analysing changes to a machine’s behaviour and performance, these systems can monitor physical parameters and identify possible maintenance requirements before they cause unnecessary and costly repairs or machine downtime. The main advantages of this are reduced maintenance costs, reduced machine downtime, greater flexibility and reliability, and increased safety.

In this blog, we’ll take a closer look at the specific reasons why large diesel engine monitoring should take place. Particularly long ocean voyage vessels, should be monitored using the new DOCTOR systems.

Monitoring Propulsion Engines

The diesel engine is still widely used in marine industries and power applications, specifically on long ocean voyage vessels, like tankers and containers, which generally use a large, slow speed 2 stroke engine. Naturally, regular monitoring and regular maintenance scheduling was crucial in preventing costly maintenance problems and machine failures when away at sea. This has, over time, progressed with the advent of on-line or portable monitoring systems, like the DOCTOR systems, which can be used to provide information on cylinder pressure, which in turn determines the performance level of the certain components.

Occasionally, specialised vessels, like cruise ships, ferries, oil supply boats, ice-breakers, and naval fleets, will employ 4-stroke engines. They often use multiple engines, which does introduce an element of redundancy, but overall, the cost of utilising a single DOCTOR portable system doesn’t outweigh the total price of the asset. As a result, there is a huge cost saving element involved, which has convinced many operators of these types of vessels to adopt condition monitoring systems like the DOCTOR portable.

Generators & Power Sources

Most of the power sources in these vessels and power plants are also generated by diesel engines. These are particularly critical on large, long distance vessels like cruise ships, as power failures can have catastrophic effects and even threaten the safety of passengers and crew members. Despite these serious ramifications, they are often overlooked, which can have devastating effects if power outages and issues occur at inopportune moments. Add to this the fact that four-stroke engines are generally less efficient than 2-stroke engines, and you may start to see why large vessels would consider investing in DOCTOR portable systems.

How worthwhile is the DOCTOR portable system?

Now that we’ve discussed the potential applications of the DOCTOR portable system, let’s inspect the economic viability of such an investment. If you assume that a complete portable monitoring system for three generators costs $10,000, and the lifetime of such a system is upwards of 10 years, then this investment will only cost you approximately $330 per engine per year. Not only is this a small fee to pay for the savings in maintenance and fuel costs, but it also provides peace of mind that is vital for these important industries. It will give ship owners and power station managers the confidence they need to provide a better and safer service. This is precisely the reason that DOCTOR systems are used throughout the world by major shipping companies and power stations. The Diesel Doctor has become synonymous with reliability, accuracy and user-friendliness in marine engine monitoring. For more information, visit us at www.iconresearch.co.uk.