Engine Surveillance System

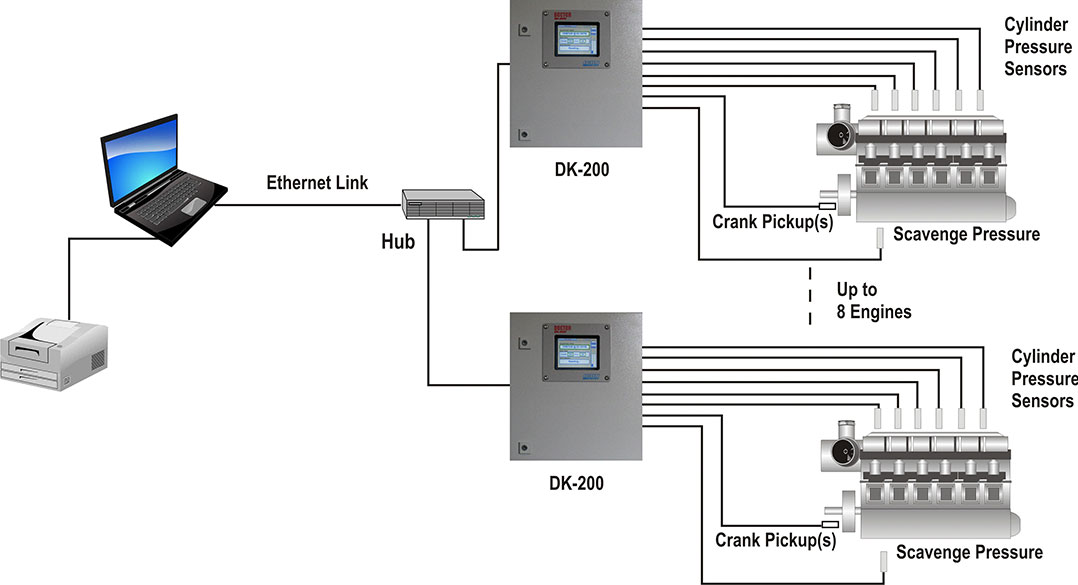

The DK-200 is a powerful combustion surveillance system that allows engines to be continuously monitored and have any issues alerted as they happen. Up to 16 cylinders can be measured simultaneously with data being transfered via an ethernet LAN to a Windows PC running the feature-rich viewing and analysis software. External viewing software means that engine performance can be observed from several locations anywhere in the world.

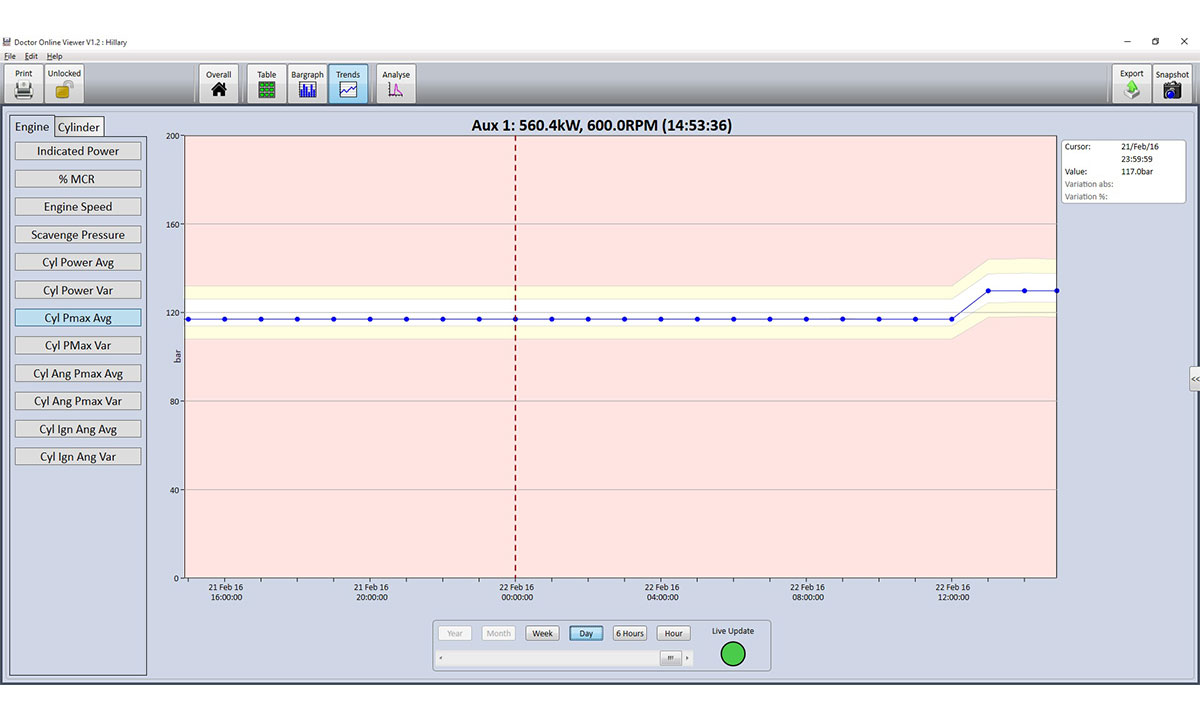

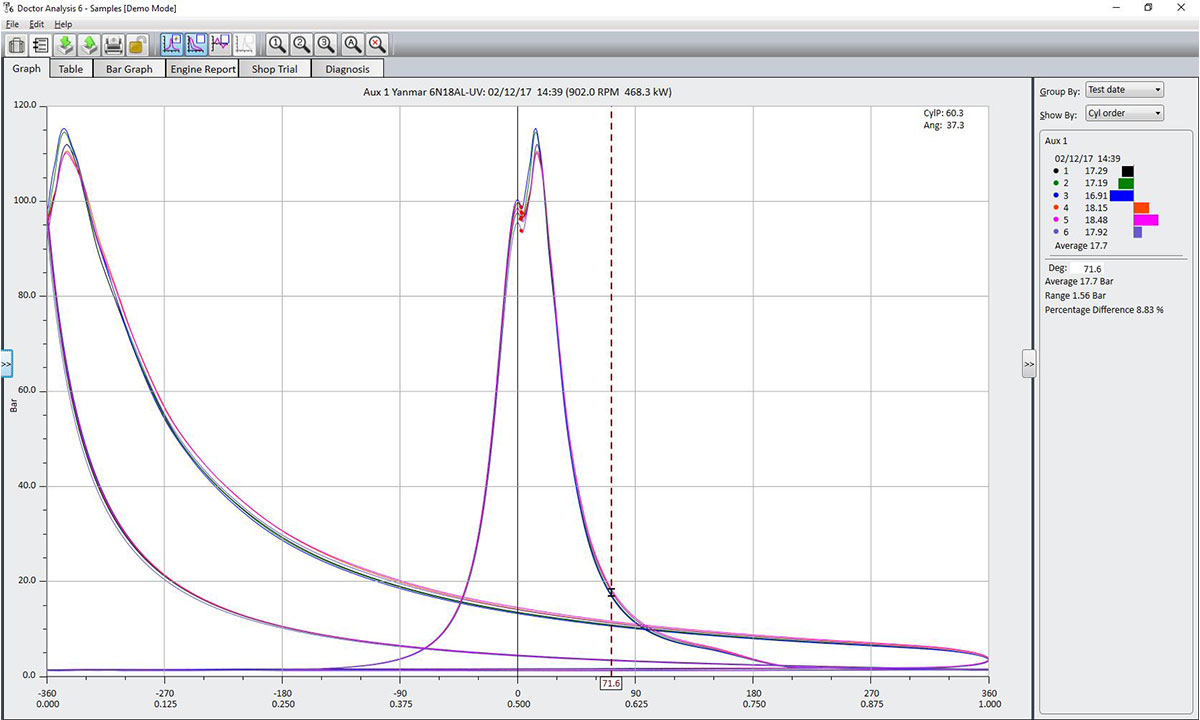

A dashboard of key user-definable parameters is displayed on the computer screen. If any value deviates from a predefined level, a colour-coded alert or alarm is raised. The software incorporates Icon Research’s powerful Version 6 analysis software enabling further analysis of pressure traces to be carried out, including cylinder and engine comparisons. Real-time displays of pressure traces are available enabling the effect of any engine adjustment to be seen as it happens.

In summary, the DK-200 system offers the ultimate in engine monitoring – simultaneous cylinder measurement with real-time display and alarming, backed up with powerful analysis tools.

Engine Condition Monitoring Solution

The diagram below shows the system configuration. Sensor and all other cabling is terminated at a single rugged enclosure. A full-colour touch screen makes setup straightforward and provides a real-time display of indicated power and engine speed in the engine room. Multiple DK-200 units are connected over the ethernet network.

Features

On-Line Analysis Software

The DK-200 engine surveillance system is supported by a comprehensive software application that displays measurements from one or more DK-200’s in real-time. Displays are configurable depending on the engine(s) being monitored, for example, number of cylinders, measurement types etc. Multiple engines, including a mix of 2-stroke and 4-stroke, can be displayed simultaneously on the dashboard.

The software can display an overall summary of the status of all engines using a simple “traffic light” summary. All green means that all measurements are with pre-determined limits. Yellow means that a measurement is slightly outside and should be checked, and red means that a close look should be taken. Clicking on a particular engine displays more detail. Going further down the hierarchy enables graphs and tables of single and multiple engines to be displayed in real time.

The DK-200 on-line software incorporates the popular Doctor Version 6 software module. This provides the full graphic and tabular displays available in Version 6. Importantly, it includes the Diagnostic option which means that instant diagnostics can be displayed for each measurement set as it comes in from the DK-200 over the network. This enables users to track in real time what may be happening on their engines.