The importance of MEMS Sensors in Condition Monitoring

The importance of MEMS Sensors in Condition Monitoring

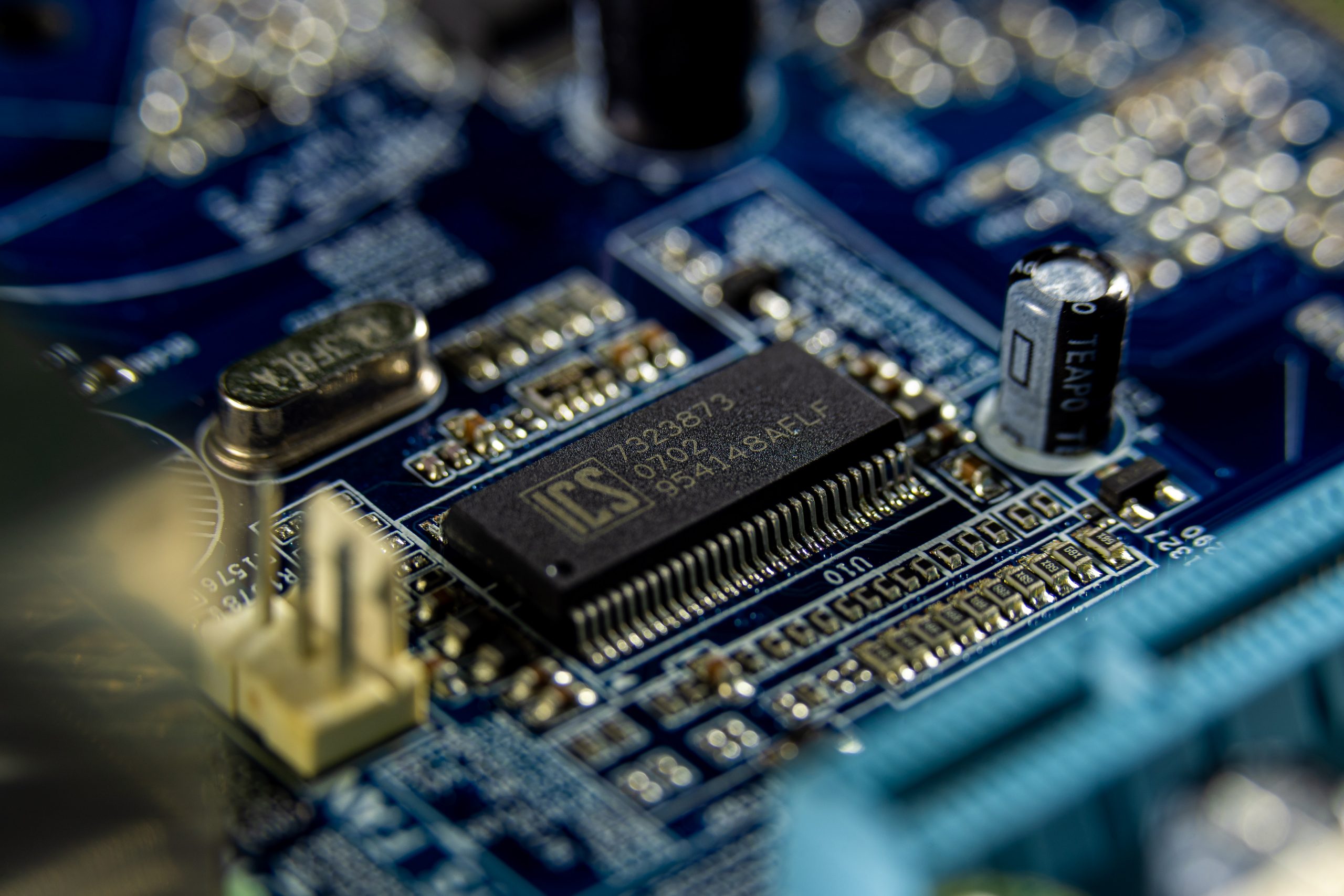

MEMS Sensors are playing a vital role in the development of complex technologies and refined electrical devices. However, their applications are now not only limited to consumer devices, like mobile phones, but also have become a staple of condition monitoring equipment (especially vibration monitoring).

In this blog, we will highlight the importance of MEMS Sensors while discussing their crucial role in the ongoing development of condition monitoring equipment.

Precision & Accuracy

MEMS Sensors ensure that all measurements are reliable and accurate, which means you never have to second guess your data or your measurements. As a result, they can be easily deployed for both commercial and industrial uses and can be integrated with a variety of applications. They are particularly central to our WiVib Range of products, which focus on vibration monitoring, temperature monitoring, and bearing monitoring.

Fusing Analog Signals with Digital Workflows

MEMS Sensors allow you to combine analog signals and processes with refined digital interfaces and analytics which gives you powerful insights into the performance of your machinery. After all, data like pressure, temperature, acceleration, and humidity are relatively invaluable unless we can process the data in a useable manner. It is the sheer affordability and reliability of these sensors themselves that allow them to be used in conjunction with more complex digital workflows, many of which require extensive development and integration. Without the digital component, effectively acting as a translation device between the analog sensors and your cloud-based applications, the raw data becomes relatively difficult to process.

Minimal Weight & Size, Remarkable Performance

This accuracy does not, however, come at a higher price point than other, traditional sensors. In fact, MEMS Sensors are the most widely deployed sensors in the world, due to their cost-effective nature. One of the main elements that keep costs down is the minimal weight and size of these sensors.

MEMS accelerometers are now challenging the traditional piezo-electric devices in terms of bandwidth and dynamic range. Coupled with lower cost and small size, MEMS devices have now broken through into the mainstream of condition monitoring. While the weight of these Sensors is particularly important in the development and refinement of personal electronic devices, like smartphones, controllers, digital picture frames, and smartwatches, it also has a pivotal role to play in engine condition monitoring and machine monitoring. For example, the aeronautical sector is always immensely concerned about extra weight, as any excess weight costs them significant amounts of money. Any size, but more importantly, weight savings, even just a few pounds, can save thousands on each aircraft, each flight. And many other applications are no different, especially if they are placed in remote locations or must withstand tough environmental conditions. Strength and durability are key, but keeping costs down is the only way to make these MEMS Sensors viable with regards to condition monitoring.

Icon Research

MEMS technology is at the very forefront of some of the most inspiring and innovative technological advancements in the world. At Icon Research, they form the crucial backbone of our condition monitoring units, which are widely used for diesel engine applications and vibration condition monitoring. Please contact us for more information regarding our products.

MEMS accelerometers are now challenging the traditional piezo-electric devices in terms of bandwidth and dynamic range. Coupled with lower cost and small size, MEMS devices have now broken through into the mainstream of condition monitoring.