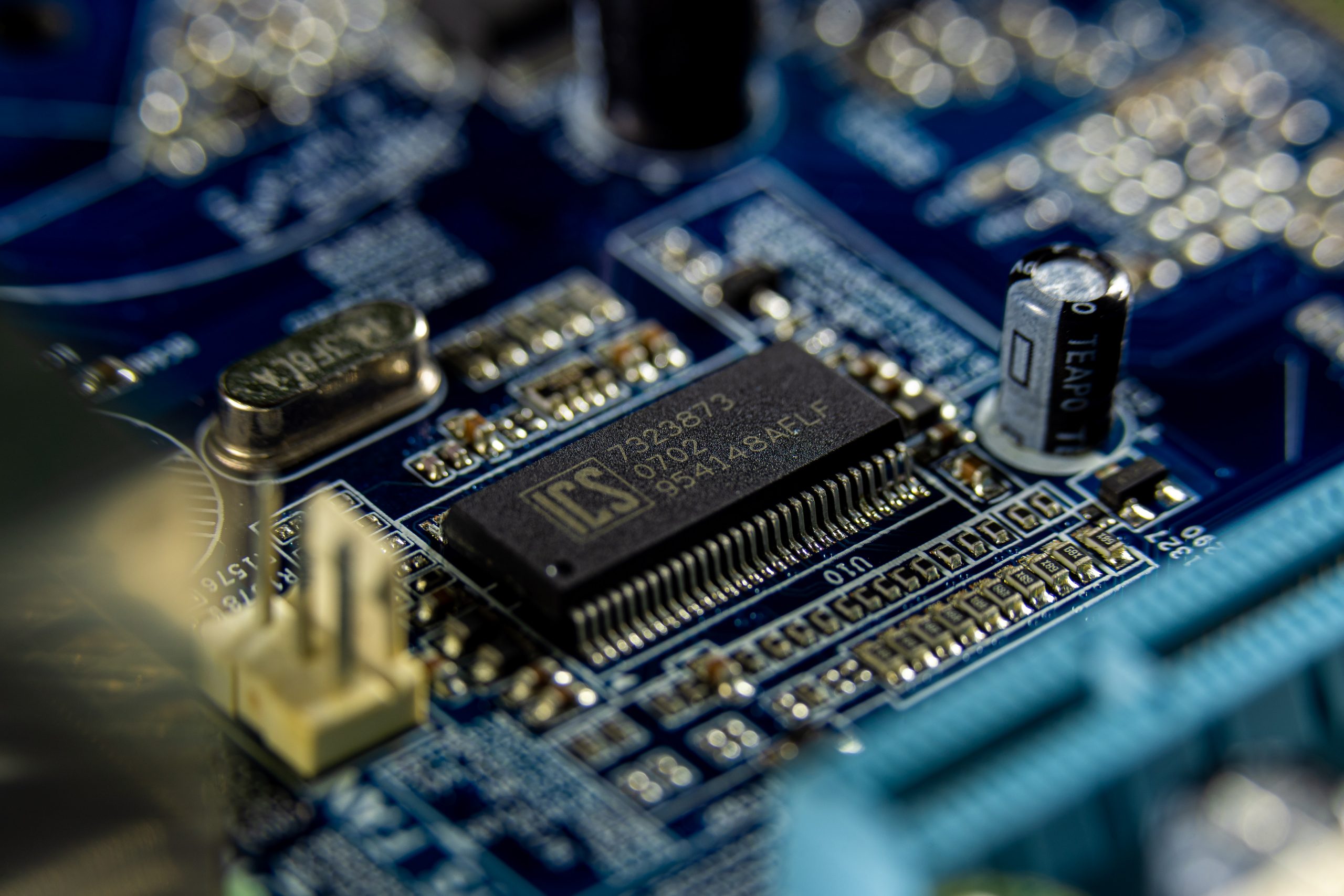

The Impact of Electrical Component Shortages on the World: A Detailed Explanation

The global manufacturing industry is currently experiencing a major shift that is impacting supply chains around the world. Shortages of materials and components in a number of industries have driven up prices and led to shortages of some goods. This blog post will take a close look at this phenomenon and explain the causes, the impact, and ways we at Icon Research aim to mitigate the risk.

What is causing supply chain disruptions?

Electrical component shortages have been affecting the manufacturing supply chains in many industries around the world. Major companies in consumer electronics, the automotive industry and beyond have been affected by these component shortages. Some of the reasons for shortages of components include extremely high demand from users, tariff-related issues, and market normalisation. China’s tariffs on imported components have led the country’s component manufacturers to begin to import essential components from other countries to maintain production levels.

Shortages of materials

The global demand for components is increasing at an exponential rate. Although there are other factors that are impacting the supply of these components, one of the primary causes of the shortages is the increase in the demand for raw materials. The semiconductor industry requires large quantities of mined ores. Covid has reduced productivity as well as affecting global distribution of these basic materials.

Shortage of Fabrication Capacity

Increased demand for semiconductors has put pressure on the finite resources of the fabrication plants, or ‘fab plants’ around the world. Being unable to meet demand has meant that certain types of semiconductor find themselves well down the ‘queue’, resulting in delivery times often of more than one year, and sometimes even two years. There is a rush to build more fab plants, especially outside Asia, but it will be a while before these come onstream.

Factors affecting the price of goods

Insatiable demand and the factors mentioned above have been compounded by stockpiling. The production of an automobile can be held up due to the non-supply of a single semiconductor costing a few dollars. In times of shortage, manufacturers will hoard these vital components to make sure that they can keep their production lines moving. And, of course, this leads to higher prices. Semiconductors are changing hands at many times the price they were a couple of years ago

Ways to mitigate supply chain risks

There is no magic wand to solve this problem in the short term. Forward ordering helps in the medium and longer term. Companies are even resorting to redesigning their products to use components that are more readily available. Greater emphasis is being put on inventory control to manage the situation. However, forward purchasing puts pressure on cash flow if components have to be bought while they are available to hedge against a future shortage.

Key Takeaway

Icon Research is not immune to this global crisis and we have spent a lot of time managing the situation. We are maintaining a buffer stock of a large number of component types and forward ordering to mitigate problems in the future. It is clear that this problem will be with us for a while, probably 2-3 years at least. Some of our production has been affected and we thank our customers for their patience when deliveries have not met expectations.