An Overview of MEMS Sensors & How They Work

MEMS has been identified as one of the most promising technologies and impacts both industrial and commercial products by combining silicon-based microelectronics with micromachining technology. MEMS sensors are a significant part of the Internet of Things (IoT), hence condition monitoring products that adopts a MEMS accelerometer as the core sensor helps to reduce overall cost of deployment and ownership, while ensuring all measurements are reliable and accurate.

The WiVib Q series from Icon Research uses the latest MEMS sensing elements as is an integral part of our condition monitoring units for reliable long-term measurement. These are widely used for diesel engine applications, vibration condition monitoring, temperature monitoring, and bearing monitoring.

In this blog, we will discuss what MEMS Sensors are and explain how they actually work.

MEMS Sensors Explained

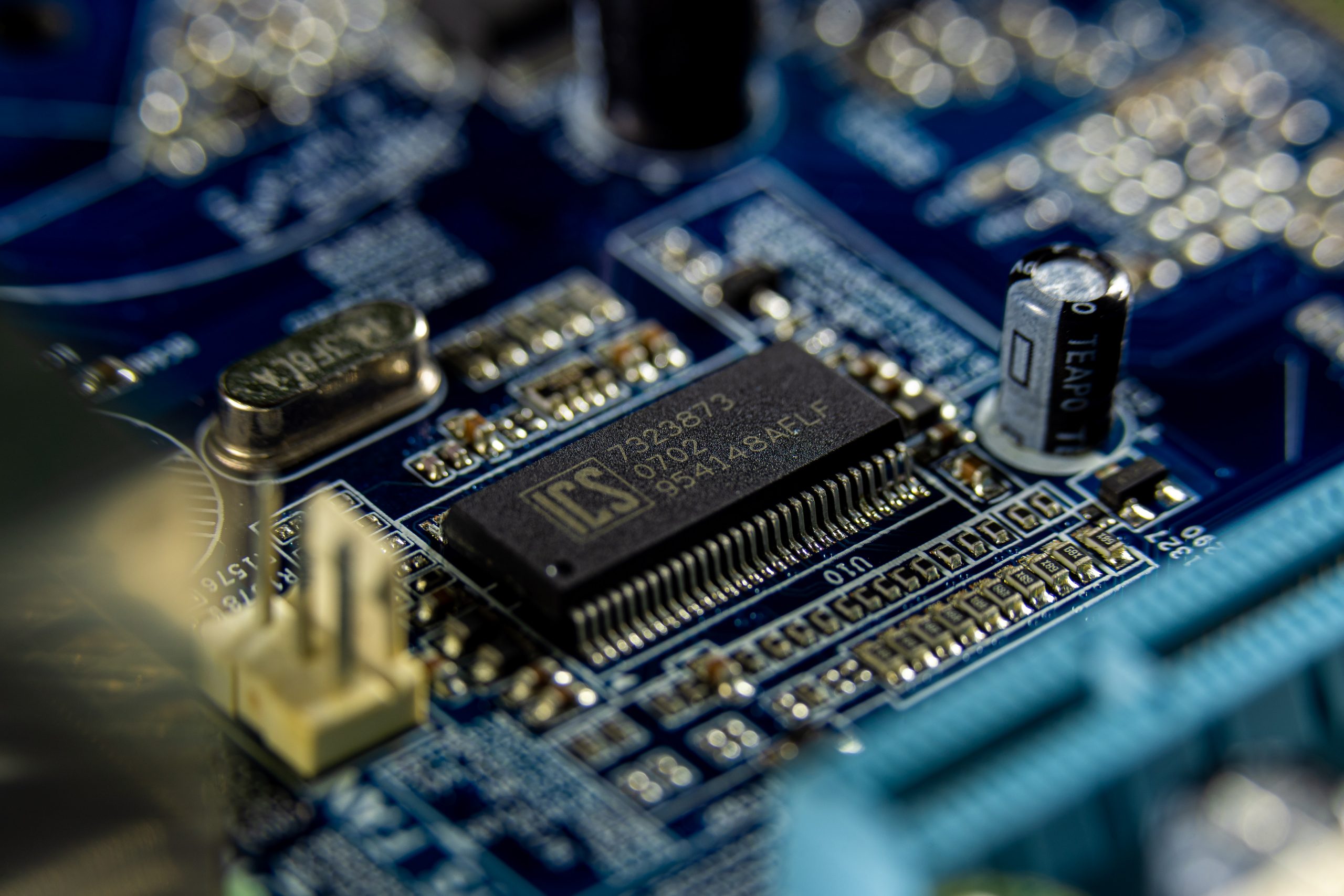

MEMS sensors integrate Electrical and Mechanical components together into or on a single chip using techniques of microelectronic fabrication, meaning they are electro-mechanical sensors (a chip-based technology). As such, MEMS sensors represent a continuum bridging electronic sensors at one end of the spectrum, and mechanical sensors at the other that allows the microsystem to both sense and control the environment.

They are microscopic devices, typically etched from a layer of silicon and secured inside a very small enclosure with integrated electronics. Therefore, MEMS sensors can range in dimension size (i.e. from a few microns on the lower end of the dimensional spectrum to millimetres), as well as varying in complexity of MEMS devices from having relatively simple structures to highly complex electromechanical systems.

MEMS sensors are highly reliable, durable, have lower power consumption, achieve the required performance, and is a cost-effective alternative due to mass production, which is particularly relevant when the price is a major factor for you. Like our solid wireless condition monitoring system, our WiVib range is strong, sturdy, reliable to be both functional and reliable. With these advantages, MEMS sensors is the mainstream for the future of vibration measurement based condition monitoring.

How They Work

MEMS sensors are made up of a suspended mass between a pair of capacitive plates. Suspended mass creates a difference in electric potential whenever tilt is applied to the sensor (measured as a change in capacitance). That signal can then be amplified to produce a stable output signal, such as in digital, 4-20mA or VDC.

More Information

Need more information about our WiVib Q products fuelled by MEMS sensing elements? Contact us today!