Icebreaker Uses Diesel Doctor DK-100 Engine Analyser for Tuning and Fault Identification

IB Ymer is one a number of Icebreakers owned by the Swedish Maritime Administration under operational and technical management of Viking Supply Ships. She can generate a total power of around 19,000kW supplied by 5 Wartsila Pielstick 12PC2-2 V12 main engines. These engines have a common rail injection system on which the engineers can easily make timing adjustments. A system was required to quickly evaluate the results of these changes to optimise performance.

In order to meet the requirements of the Ymer engine crew, Icon developed the DK-100 as a portable engine analyser with multi-cylinder simultaneous sampling capability. The pressure sensors used are the Kistler 6613CG1 designed for on-line use with medium speed 4-stroke engines.

![]()

The system can be moved from engine to engine on the Ymer and transported to different vessels to test and tune their engines.

The initial DK-100 system was housed in a metal box. Future systems will be supplied in a “suitcase” style rugged yellow plastic box for better portability. The screen refresh rate is approximately ten seconds but this will be improved to 1-2 seconds in the next version of the system. The DK-100 is particularly useful with gas or dual-fuel engines for overall tuning, analysis and knock detection.

The solution was delivered and tested successfully. The fuel injection timing can be adjusted in 0.1-degree steps and the resulting changes in values such power, Pmax, and Pcomp can be seen in real-time.

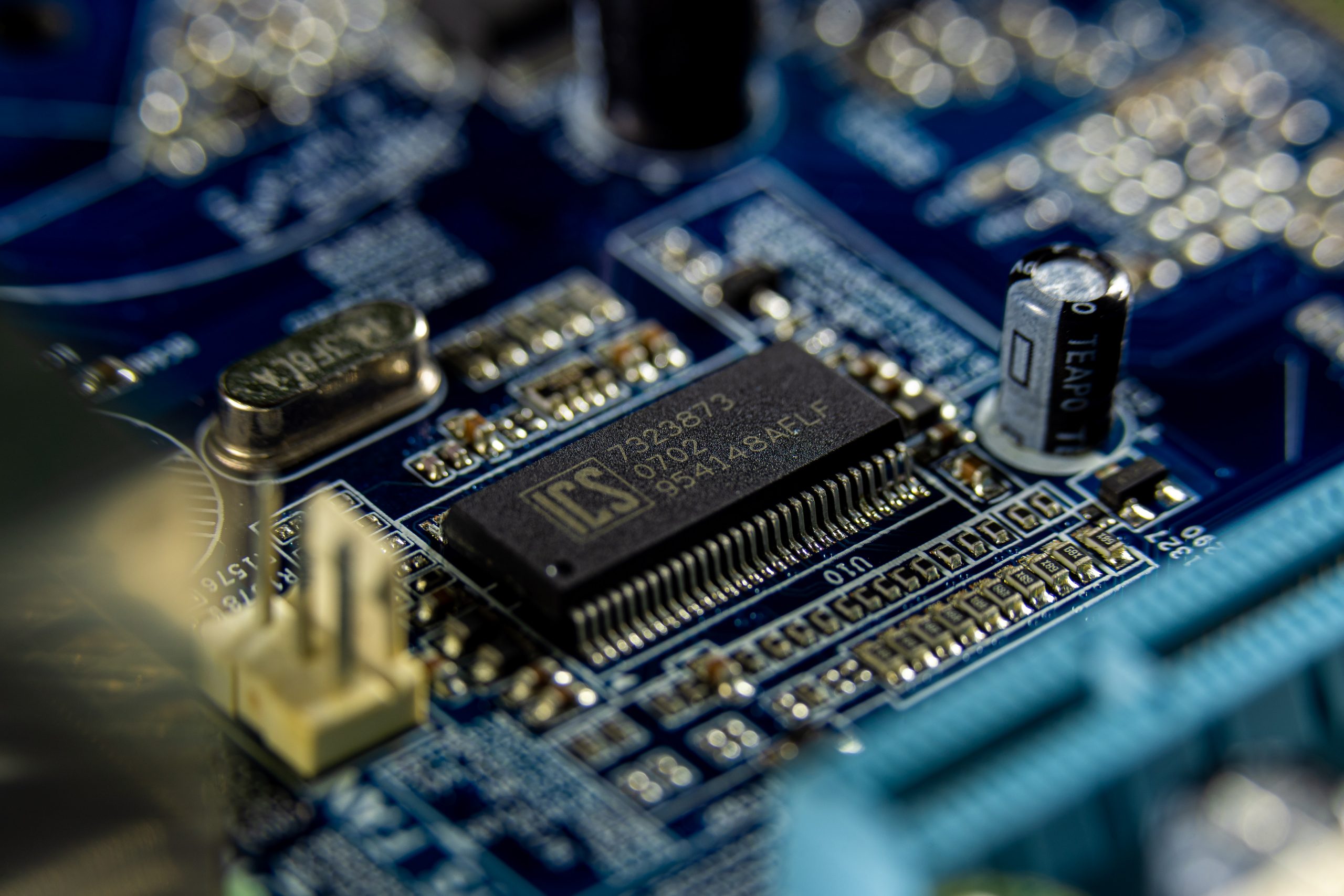

The screenshot below shows the trace for the derivative of the pressure versus angle curve of all 12 cylinders. The derivative is a useful tool in visualising the rate of pressure change identifying events such as ignition timing and Top Dead Centre position. Note that all 12 cylinders are measured simultaneously.

![]()

Relative comparisons between different cylinders can be carried out to pinpoint those behaving differently from the rest.

![]()

Individual cylinders can be selected and their performance over time analysed as shown in the screenshot above where cylinder A1 has been selected and three separate readings overlaid. This can identify deterioration in engine components such as fuel injectors, pumps, piston rings and cylinder liner wear.

The Doctor Diagnostic software automatically diagnoses and reports these issues.

DOCTOR systems are used throughout the world by major shipping companies. The Diesel Doctor has become synonymous with reliability, accuracy and user-friendliness in marine engine monitoring. Find out more about our DOCTOR systems here.